components be mounted on both sides of a fpc pcb

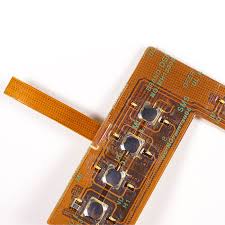

FPCs are a type of printed circuit board that is flexible and can be cut to fit a specific product. They are used in mobile phones, LED strips, automobiles, and other consumer electronic products. This is because they reduce the size and weight of the product while maintaining functionality. Using them reduces the amount of wiring needed for the product and eliminates the need for connectors. This helps to reduce manufacturing costs, making it an ideal choice for many applications.

The best way to describe what a fpc pcb is is by comparing it to a rigid PCB. The term “PCB” is short for printed circuit board, and we are all familiar with rigid PCBs that help to connect various components in a device. However, the fpc is much more flexible and can be bent and twisted at will. The fpc is also more durable and can be used in devices that are exposed to harsh environments such as those found in vehicles or outdoor electronics.

A fpc pcb is made from thin sheets of polyimide that have copper on one or both sides. These sheets are then etched to create traces that conduct electricity, and they are covered with a protective layer. After the etching and protective coating processes are complete, they can be drilled to make holes for connecting components. These holes are then metalized to form conductive paths between the layers of the fpc.

Can components be mounted on both sides of a fpc pcb?

In order to determine which fpc is right for your product, it is necessary to consider the material stack-up and design of the circuit. Single-sided fpcs are ideal for simple designs as they can be bent freely and help to reduce the space required for wiring. Double-sided fpcs allow more complex designs to be built as they can be used on both sides and have the ability to endure repeated bending.

Another consideration when choosing an fpc is the thickness. The fpc should be thin enough to bend and flex, but thick enough to maintain durability and functionality. JHDPCB offers a variety of different fpc thicknesses to ensure that you can find the perfect one for your needs.

The final aspect to consider when choosing an fpc is the layering system. The fpc can be constructed with one or two layers of copper and the surface can be insulated. This allows for a number of different connections to be made between the fpc and other components in your product. This allows for a cleaner and more functional design while reducing the risk of human error in wiring.

FPCs are a great option for your next project. Their flexibility and low cost make them an ideal choice for most electronic products, especially those that need to be mobile or require a compact design. They are easy to work with, and they can help you save time and money by eliminating the need for wires and connectors. With a fpc, you can easily connect your products and ensure that they look professional.