Turnkey PCB Assembly Handle Multi-Layer PCBs

Turnkey PCB assembly is a way to streamline the manufacturing process for electronic devices. Instead of outsourcing different production stages to multiple vendors and waiting for all the pieces to come together, a full turnkey electronics contract manufacturer can take care of everything from design to delivery. However, not all electronics contract manufacturers offer full turnkey PCB assembly, and it’s important to know what to look for.

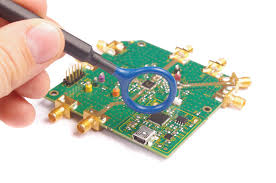

Multilayer pcbs are a type of printed turnkey pcb assembly that have multiple copper layers. These layers are arranged in various configurations to create the desired circuitry. Electrical links between the layers are established through plated vias and blind or buried vias. There are many advantages of using a multi-layer PCB, including higher performance, greater EMI shielding and the ability to balance size and functionality.

However, when creating a multi-layer board, designers need to consider the impedance of each layer and how it will affect other layers. The material that is used for fabrication will also have an impact on the performance of the final product. A good PCB designer will be able to help with this, providing the right materials and layer configurations for the best results.

Can Turnkey PCB Assembly Handle Multi-Layer PCBs?

Getting a high-quality, multi-layer PCB can be a challenge because of the extra work involved. It’s a great idea to choose a manufacturer that is experienced with handling complex projects and can handle all the necessary tasks. This will ensure that the finished product is as expected.

In addition, choosing a manufacturer that offers quick turnaround times and cost-effective pricing is crucial. This will allow you to meet your deadlines and reduce stress levels. It is also worth checking out the reputation of the manufacturer to make sure that they can deliver on their promises.

Another key benefit of working with a turnkey electronics contract manufacturer is that it can save you time and money by eliminating the need to manage multiple suppliers. This will reduce the chances of miscommunication, which can derail timelines and lead to wasted expenses. A turnkey CM will provide you with a single point of contact for all business. This will improve the efficiency of the project and decrease production costs.

When using a turnkey electronics contract manufacturer for PCB manufacturing, you should always check for quality assurance. This includes automated optical inspection (AOI) and functional testing. AOI can spot defects in the finished product and help identify problems early on in the manufacturing process. This will prevent expensive errors and delays later on in the production process.

If you’re looking for a full-service contract manufacturer to handle your multi-layered PCB project, look no further than Sierra Assembly. Our team has the experience and expertise to deliver a high-quality product. Our services include PCB design, assembly and test, as well as systems integration. We can also assist with your component selection and sourcing. To get started, request a quote from us today. We offer free quotes and no minimum orders.