PCB printed circuit board assembly support flexible electronics

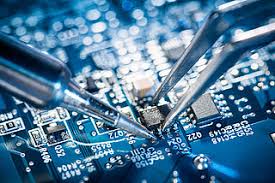

Flexible electronics, characterized by their ability to bend, stretch, and conform to various shapes and surfaces, represent a paradigm shift in the design and functionality of electronic devices. At the heart of this revolution lies PCB (Printed Circuit Board) assembly, playing a pivotal role in enabling the development and deployment of flexible electronic products. By leveraging advanced materials, innovative manufacturing processes, and flexible PCB designs, PCB assembly supports the realization of flexible electronics across a wide range of applications, from wearable devices to bendable displays and beyond.

One of the primary ways in which PCB assembly supports flexible electronics is through the adoption of flexible substrates and materials. Flexible PCBs, also known as flex circuits, are designed to bend and flex without compromising electrical performance or reliability. These flexible substrates, typically made of polyimide or polyester films, allow for the creation of lightweight, compact, and conformable electronic assemblies that can be integrated into flexible or curved surfaces. By incorporating flexible materials into PCB designs, manufacturers can overcome the limitations of rigid PCBs and unlock new possibilities for innovative product designs and form factors.

Moreover, pcb printed circuit board assembly techniques tailored for flexible electronics play a crucial role in ensuring the integrity and functionality of flexible PCB assemblies. Advanced assembly processes such as roll-to-roll (R2R) manufacturing, laser ablation, and direct metallization enable high-speed, high-precision fabrication of flexible PCBs on flexible substrates. These techniques allow for the deposition of conductive traces, component mounting, and soldering in a manner that accommodates the unique mechanical properties and requirements of flexible materials. By optimizing assembly processes for flexibility, manufacturers can produce flexible PCB assemblies with exceptional mechanical durability, electrical performance, and reliability.

How does PCB printed circuit board assembly support flexible electronics?

Furthermore, PCB assembly supports flexible electronics by facilitating the integration of diverse electronic components and technologies into flexible form factors. Components such as surface mount devices (SMDs), chip-scale packages (CSPs), and bare die can be mounted directly onto flexible substrates using advanced assembly techniques such as flip-chip bonding and embedded component placement. Additionally, advancements in interconnect technologies, such as flexible interconnects, microvia drilling, and conductive adhesives, enable reliable electrical connections between components and flexible traces, ensuring seamless functionality and performance in flexible electronic assemblies.

In addition to supporting flexible PCB fabrication and assembly, PCB assembly techniques also play a vital role in ensuring the reliability and durability of flexible electronic products. Flexible PCB assemblies are subjected to unique mechanical stresses and environmental conditions, including bending, stretching, vibration, and temperature variations. As such, reliability testing and quality assurance during PCB assembly are essential to ensure that flexible electronic products meet stringent performance and reliability requirements. By conducting comprehensive testing, including mechanical bending tests, thermal cycling, and environmental stress testing, manufacturers can validate the robustness and durability of flexible PCB assemblies and mitigate the risk of premature failures in the field.

Moreover, PCB assembly supports the scalability and commercialization of flexible electronics by offering cost-effective, high-volume manufacturing solutions. As demand for flexible electronic products continues to grow, PCB assembly technologies and processes are evolving to meet the needs of mass production. Advanced manufacturing techniques, such as continuous roll-to-roll processing and high-speed pick-and-place assembly, enable efficient, high-yield production of flexible PCB assemblies at competitive costs. By optimizing production workflows, minimizing material waste, and maximizing throughput, manufacturers can achieve economies of scale and drive down the cost of flexible electronic products, making them more accessible to consumers.

In conclusion, PCB printed circuit board assembly plays a crucial role in supporting the development, production, and commercialization of flexible electronics. By leveraging flexible substrates, innovative assembly techniques, and reliability testing protocols, PCB assembly enables the creation of flexible PCB assemblies with exceptional mechanical flexibility, electrical performance, and reliability. As the demand for flexible electronic products continues to rise, PCB assembly will remain a cornerstone of flexible electronics innovation, driving advancements in wearable technology, flexible displays, IoT devices, and beyond.